Using Engine Oil in a Hydraulic System

It is common practice in the construction industry to use multigrade engine oil as a replacement for hydraulic oils. This practice is recommended by some manufacturers but not by others, so what are the benefits and drawbacks?

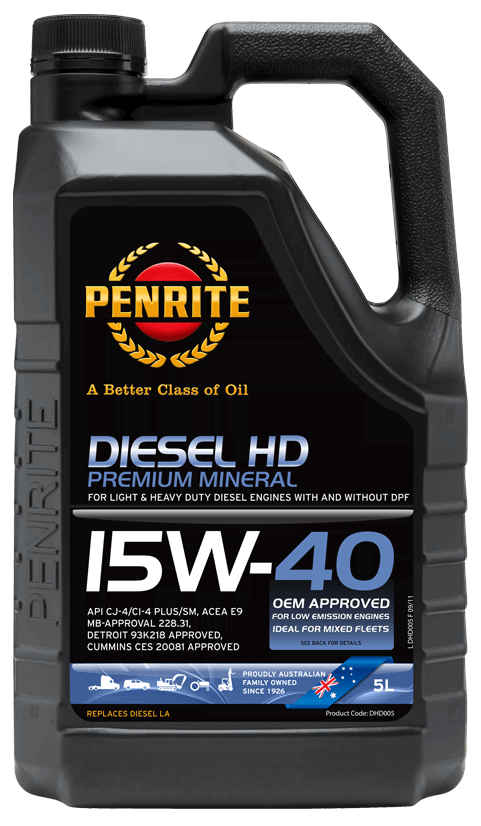

The main benefit of multigrade engine oil when used as hydraulic oil is the fact that multigrade engine oils must fulfil  two viscosity specifications, for example, 15W-40, 15W for ‘winter’ and 40 for ‘summer’. This can be a real benefit for systems running in a wide range of ambient temperatures, such as is found in Australia. It is therefore very common practice for multigrade engine oil to be used as hydraulic fluid in skid-steer loaders.

two viscosity specifications, for example, 15W-40, 15W for ‘winter’ and 40 for ‘summer’. This can be a real benefit for systems running in a wide range of ambient temperatures, such as is found in Australia. It is therefore very common practice for multigrade engine oil to be used as hydraulic fluid in skid-steer loaders.

Modern multigrade engine oils also use detergent additives to help ‘clean’ the engines that they are designed for. The general consensus is that this is also a benefit for most hydraulic systems. The detergent additives help prevent sludge and varnish build up in the hydraulic systems, which is why detergent additives are also found in higher grade hydraulic oils such as HDLP, or oils with HVI (High Viscosity Index) improvers.

The main drawback from using multigrade engine oil over hydraulic oil is that engine oils have excellent water emulsifying properties, whereas good quality hydraulic oils have great water dispersing properties. This is generally not an issue, as a well maintained hydraulic system should have very low water content (less that 0.1%).

Regardless of what oil is used in the hydraulic system, the most important procedure is to follow the guidelines of the manufacturer. If using multigrade engine oil, it is recommended that the oil be changed at the manufacturers’ recommended intervals, and most importantly the filter changed at the recommended intervals. If the content of water is too high, it can hamper the effectiveness of the hydraulic filter, causing it to bypass prematurely.