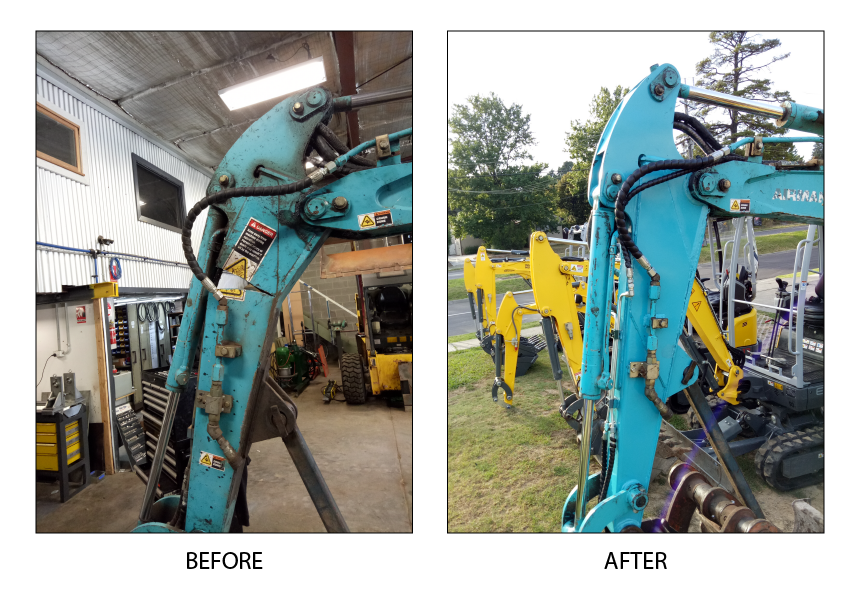

Airman AX27U-4 Arm Repair

Date Posted:15 March 2017

This week in the ACES workshop we repaired a broken dipper arm on an Airman AX27 (Hitachi Z axis ZX27). The arm had been engineered for use with a “stiff-arm” grapple. Stiff arm grapples place an enormous amount of pressure on the dipper arm of excavators. Often after a few years of use they will start to fatigue, and then eventually crack. If the cracking is not spotted in time, the arm will break relatively quickly, such in the case of this excavator.

To make this repair we firstly removed the arm and completely disassembled it. Next we separated the two halves of the arm and straightened the bent sections along the joint. Once the joint was straightened we prepared it for welding, and realigned the arm using the pivot pins at both ends. The arm was then butt-welded back together, with the welds ground down flush with the base metal.

The next step was to cut bracing plates for all four sides of the arm to strengthen the arm while adding minimal weight to it.

We also made sure that the bracing did not look out of place on the arm. All too often we see poorly repaired arms that take thousands of dollars off the re-sell value of the machine. We welded the bracing in place and finished it off with a coat of paint colour matched to suit.

Lastly we manufactured new quick hitch lines for the machine and fitted them on final assembly. This was all completed for a fraction of the cost of a replacement arm, and within a fraction of the time to ship a new one in from Japan.