Auger Hitches: Standard vs Cradle vs Swing Control System

When purchasing a new auger for your excavator or loader, there are a range of options as to how the swing of the auger is controlled. Most commonly supplied and used is a standard 4-way swing hitch on an excavator, but is this the best option for you?

This standard hitch supplied on excavators allows the auger to swing in a forwards and reverse motion, and also a left and right motion, by means of two pivoting pins connecting the auger to the hitch through a linkage.

This is a cheap and simple option and is fine for use on smaller augers. The drawbacks are that it can make the auger a little difficult to connect to the machine on heavier units, and the hoses of the auger drive are more easily damaged during transport, removal and connection to the machine.

The next option is a hitch with cradle. This option has three benefits over the standard hitch. Firstly, when connecting, disconnecting and transporting in a ute or trailer, the auger will sit in the cradle of the hitch without the chance of damage to the hydraulic hoses. Secondly, as the hitch with cradle does not move freely, it makes connecting and disconnecting the hitch to the machine very simple and safe. The third benefit comes when moving around the jobsite; the auger drive can sit into the cradle so it will not sway side to side when driving. However, this is not recommended if a drill is connected to the drive as the extra weight of the drill will put too much force on the case of the drive and on the cradle itself, causing damage, as it is not designed for this.

without the chance of damage to the hydraulic hoses. Secondly, as the hitch with cradle does not move freely, it makes connecting and disconnecting the hitch to the machine very simple and safe. The third benefit comes when moving around the jobsite; the auger drive can sit into the cradle so it will not sway side to side when driving. However, this is not recommended if a drill is connected to the drive as the extra weight of the drill will put too much force on the case of the drive and on the cradle itself, causing damage, as it is not designed for this.

The downside of a cradle is that inexperienced operators may bind the cradle into the drive when in operation, which will cause damage to the auger drive and cradle. Cradles are supplied as standard on all skid steer auger drives, because during operation the chance of binding on a skid steer is much lower than on an excavator.

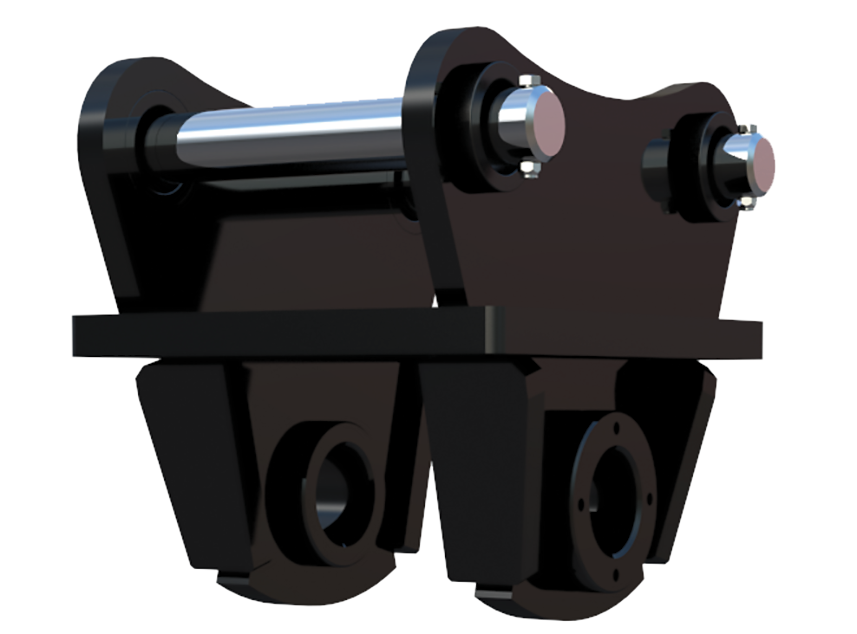

The last option is a swing control system. This is the best option, but also the most expensive, and is recommended on all large auger drives. The swing control system uses dampeners to control the 4-way swing of the auger, and also has the option of a cradle when transporting the auger. When moving the excavator or loader around site with an auger drive and auger connected to it, it can be quite dangerous as sudden movements will cause the drill to swing violently. This can be very dangerous to anyone standing near the machine and also the operator of the machine. The swing control system stops the violent movement of the auger, and by design of the system, the faster the drive swings to one side, the faster it will slow down in the opposite direction. Slowing the swing of the auger also makes it more productive, as the operator has to less waiting time between drilling holes.

Check out this video demonstrating the swing control system from Digga.

.png)